All businesses have one goal, and that is to “stay in business”.

This can only be achieved with a profitable mode of operation that creates a positive cash flow result. Passion for the product we sell at a dealership will only take the business so far.

OK, by now you are thinking ‘So what?”

I don’t contend that my readers, who are businessmen and women, do not know these fundamental facts, but my experience has shown that over time they get forgotten or at least overlooked. This perspective of mine is not me speaking from a lofty pulpit. I learned these lessons the hard way a long time ago. I don’t want other dealers to learn this with the same “kick in the teeth” so the following are some pointers that I hope you appreciate and take into consideration.

One of the biggest cash consumers in retail dealership businesses is the Spare Parts Inventory.

If you are doubtful, I suggest you take a careful look at your balance sheet. If this is true and understood, why do managers pay so little attention to good management practices?

A poorly managed parts inventory becomes a slow and steady drag on cash resources. It is like a slow-growing cancer in your business until one day someone does pay attention to it and it is too late.

When you have to sign off on a balance sheet or write-off of several hundred thousand dollars, that is a memory that never leaves you. It is obvious that without well-functioning sales, parts, and service sectors it is difficult to have a profitable business.

Our industry is awash with data points, KPI’s, reporting functions, and industry best practice metrics, but in my experience, they either cloud our minds with too much complexity or we don’t understand what that data is telling us.

So let’s just forget about all of that “noise” from outside for a while and focus on your business.

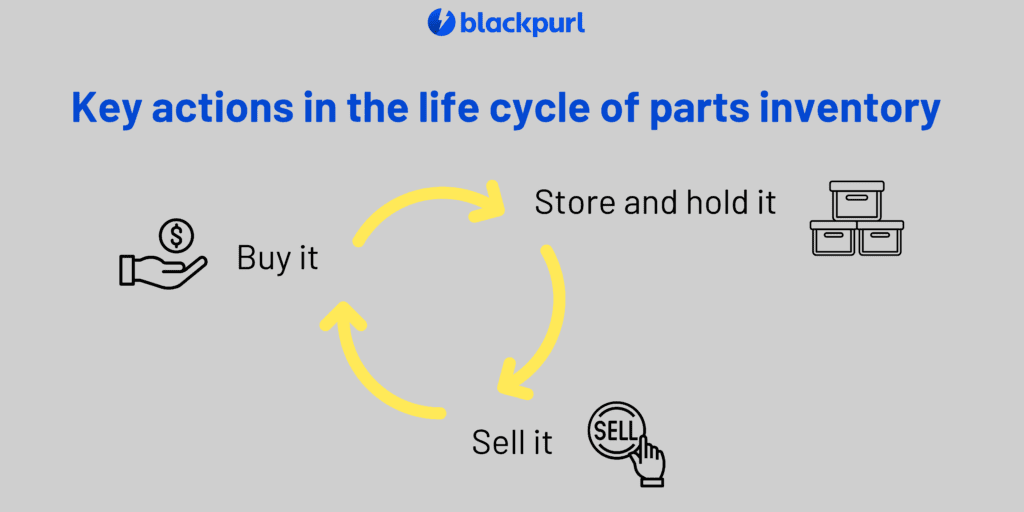

The key actions every dealer performs in the life cycle of their parts inventory management are:

- You buy it.

- You store and hold it.

- You sell it.

The nature of our business will always drag us into the frenetic customer inquiry response part of our day. This is natural and innocent because the customers are in our presence all day. This is a good thing, but without a disciplined structure in your business the buying step of our parts life cycle gets just enough attention so we are ordering what we need to fulfill immediate customer requests, and any attention to the holding stage of the life cycle is just forgotten.

This dilemma is especially prevalent in small stores where the selling, ordering, and stocking parts are required to be handled by one single person.

My challenge to all Dealer Managers is to look at your staff workflow and design a system that allows the right people to have time in their workweek to devote to good focus and management of the buying and holding stages, not just the selling.

You may need more time and resources by employing a new staff member or redeploying an existing one. And if you don’t pay attention to buying and holding activities, it will eventually sneak up and hurt your business. To help with your decision, I encourage you to make some simple budget assumptions.

Below is a simple example I used to help a customer recently.

Parts Gross Profit

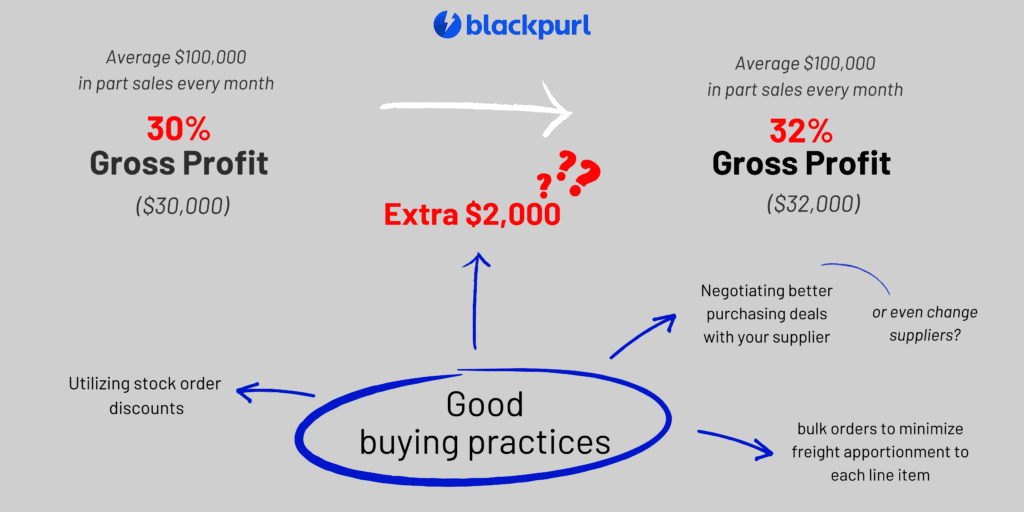

Maybe you are averaging 30% GP today. You may be satisfied with that because it isn’t as bad. But what if you could lift that to 32% through good buying practices like utilizing stock order discounts, bulk orders to minimize freight apportionment to each line item, and negotiating better purchasing deals with your supplier or even changing suppliers?

Let’s say you are averaging $100,000 in parts sales per month.

That is a Gross Profit of $30,000 @30%.

Therefore you would achieve $32,000 per month at 32%. That is an extra $2000 per month you are missing out on.

Inventory Performance.

Inventory performance is a big topic in dealer business and can take up another couple of blogs on its own.

Let’s look at two scenarios.

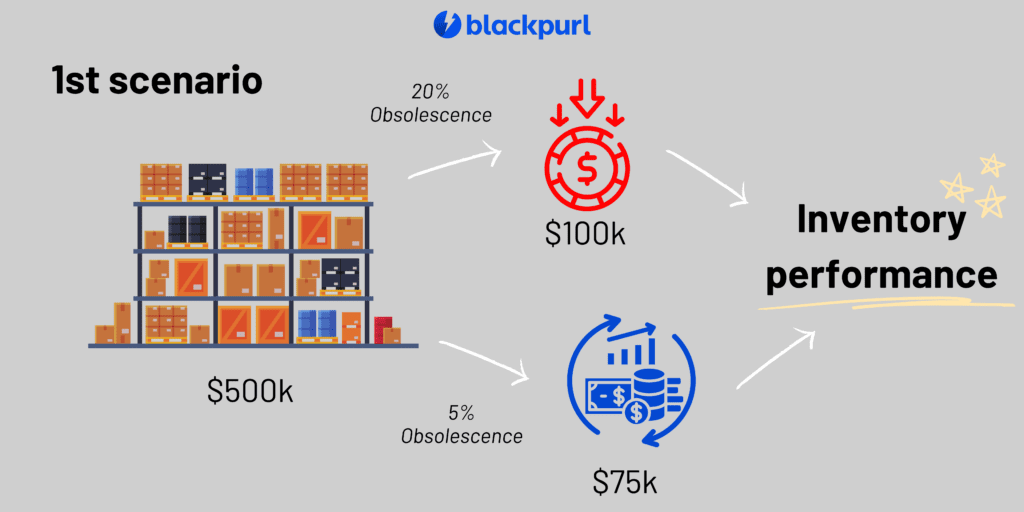

Obsolescence rate

Most dealers I encounter have an obsolescence rate of at least 20%. Holding $500K in inventory, for example, means $100K is not performing and could face a write-off. But if you pull your obsolescence back to a more manageable level of 5%, you potentially free up $75K in cash and avoid a $75K write-off.

The extra $75K is worth $4,000 a year in interest charges. Though, the likely write down to 50% value will only cost you $37,500.

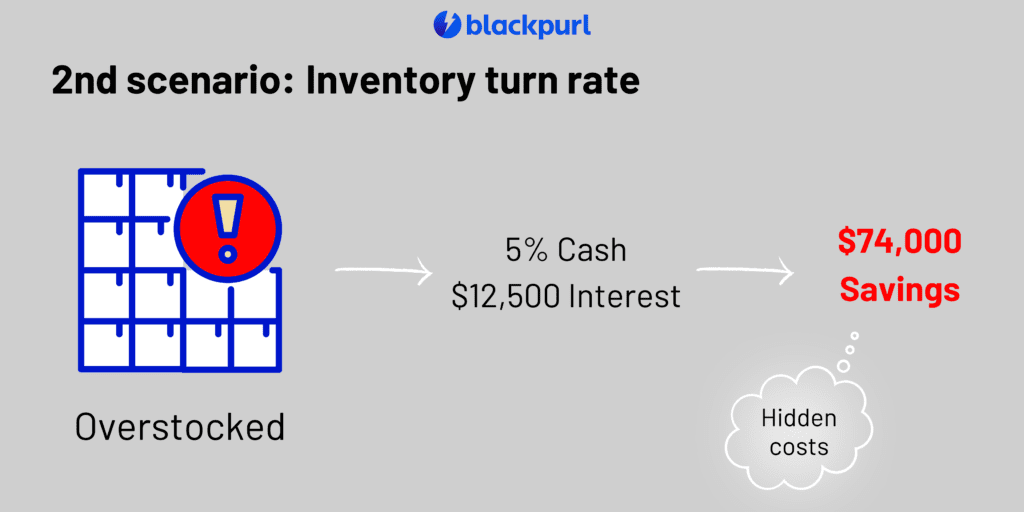

Inventory turn rate

Aim for 2-3 economic turns and 5-6 physical turns. Yet, many dealers fall short. Believe me when I say that my experience in recent years has shown me that most medium-size dealers are overstocked by at least $250,000 in comparison to best practices. This results in costs at 5% and interest at $12,500.

Adding these up potentially saves you: $24,000pa + $37,500pa + 12,500 = $74,000.

Even if you spent that money to employ somebody to focus on more efficient buying and holding practices, you cannot ignore the hidden cost savings from customer service improvements, reduced warehousing costs, and service technician productivity.

As I mentioned earlier there is a lot more detail on how to manage your inventory well, but the dollar savings do make a compelling argument to become more curious about this subject. The knowledge is available to you but you have to be willing to seek it out.

Get to know Marc!

Hello, my name is Marc Storey and I have been working with the Blackpurl team for a couple of years now. It has been an incredible journey.

To give a quick rundown of myself, I started my work career as a heavy equipment mechanic. In my early 20’s I started my own earthmoving equipment repair business. The business grew into a parts and service enterprise and eventually an Earthmoving Equipment Dealership. Several years later my wife and I started another business which was a Heavy Truck Dealership.

Over the following decades, our lifelong passion for motorcycling led us to a unique journey – we bought and developed a poor-performing Truck Dealership, which we sold after turning the performance around. Our last Dealership adventure was a greenfield business that has grown into a multi-franchise motorcycle business operating in three separate locations.

After exiting the business to allow our son to take over the management of the business, I found an opportunity to work with a Dealership Software development team at Blackpurl to help them create a new product. This experience has been invaluable in improving my understanding of how dealership software systems work and how problems for Dealers can be solved.

My interest in creating dealer management systems that ensure a smooth-running Dealership was an important ingredient in my business career success. Those skills are now helping me to mentor other Dealers and their staff on how to improve the management systems in their business and create a more valuable enterprise.